VijayaDurga Techno Systems

VDTS is mass manufacturing and supplying various types of driver’s consoles for train applications. VDTS has experience in supplying these driver’s consoles for EMU, DEMU, MEMU trains and Locomotives.

• Driver’s desks are made using polyester/phenolic resin systems complying with various national /international fire standards for stringent requirements of flammability, smoke and toxicity (FST). GRP parts of driver’s desks are made using RTM, VARTM resin infusion or conventional hand lay-up process capabilities.

Total Quality Solution

Design, Detailing, Fabrication & Erection

- Conceptual Design

- Proposal Drawings

- Detailing by Tekla Software

- Shearing & Cutting

- Full Automatic welding lines

- Shot Blasting

- Galvanized Purlins & Zinc alum Panels

- Unloading

- Erection

Pre-galvanized Secondary Members:

.............................

Z-Section:

.............................

Purlins and Girts shall be roll formed Z-sections, 120-300 mm deep with 50-100 mm flanges. Each flange shall have a 16 mm stiffening lip formed at 45° to the flange with a thickness of 1.5 to 2.5 mm.

C-Section:

.............................

C-Channels are 100-300 mm deep roll formed with 50-100 mm Flanges with a thickness of 1.5 to 2.5 mm.

Superior Built-up Sections:

.............................

Minimum thickness of 4 mm for webs, 5 mm for flange width up to 150 mm, to ensure a better-quality product.

End Wall Framing:

.............................

Superior Cladding Fasteners:

.............................

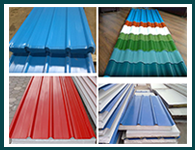

Roofing System:

Roof /wall panels are manufactured out of high strength steel grade with minimum tensile strength of 550 MPa. The steel base is coated with Zinc-Aluminum alloy with minimum AZ150(150g/m2 with minimum coating mass) as per ASTM A792.

Color coated Galvalume confirming to ASTM A792 specification has specifically formulated paint system for external roofing and wall cladding application to give aesthetical appearance for long lasting color for much longer time than any other conventional paint system.

The paint system is designed to resist chalking and fading. The painting will be baked enamel polyester or silicon polyester with a film thickness of 1.0 mil, the reverse side shall be white with 0.5 mil film thickness.

The panels shall have 30mm deep major ribs, which taper in width from 20 mm to 60 mm and are spaced 250 mm on center. Between two major ribs is additional minor stiffening ribs spaced at 46 mm on center, each panel shall provide 1000 mm coverage.

Double-Lok® System benefits

Roofing System:

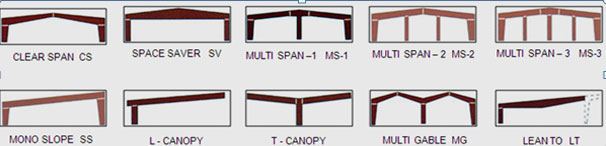

Created by VDTS professional engineers to meet your exact needs, our custom designed framing systems provide exceptional flexibility and optimum performance. Available in a wide range of shapes, sizes and layouts to suit virtually any building requirement, our framing systems are engineered to fit accurately for efficient, economical construction. All built -up members conform ASTM A570/A572 GR-50, high strength material

Valley Gutters: